Manufacturing process

- Extraction Three different types of clay are extracted and collected. These clays are mixed and stored in tanks to allow the mixture to mature over time. This maturation process is essential to enhance the quality and consistency of the clay.

- Mixing process The collected clays are combined in a standard ratio to create a uniform and suitable mixture for tile manufacturing. This ensures the mixture has the optimal properties needed for shaping and durabilit

- Cube Formation The prepared clay mixture is fed into a machine that shapes it into a large cuboid. The formed cuboid is then cut into five consistent rectangular pieces, setting the stage for the subsequent molding and shaping processes.

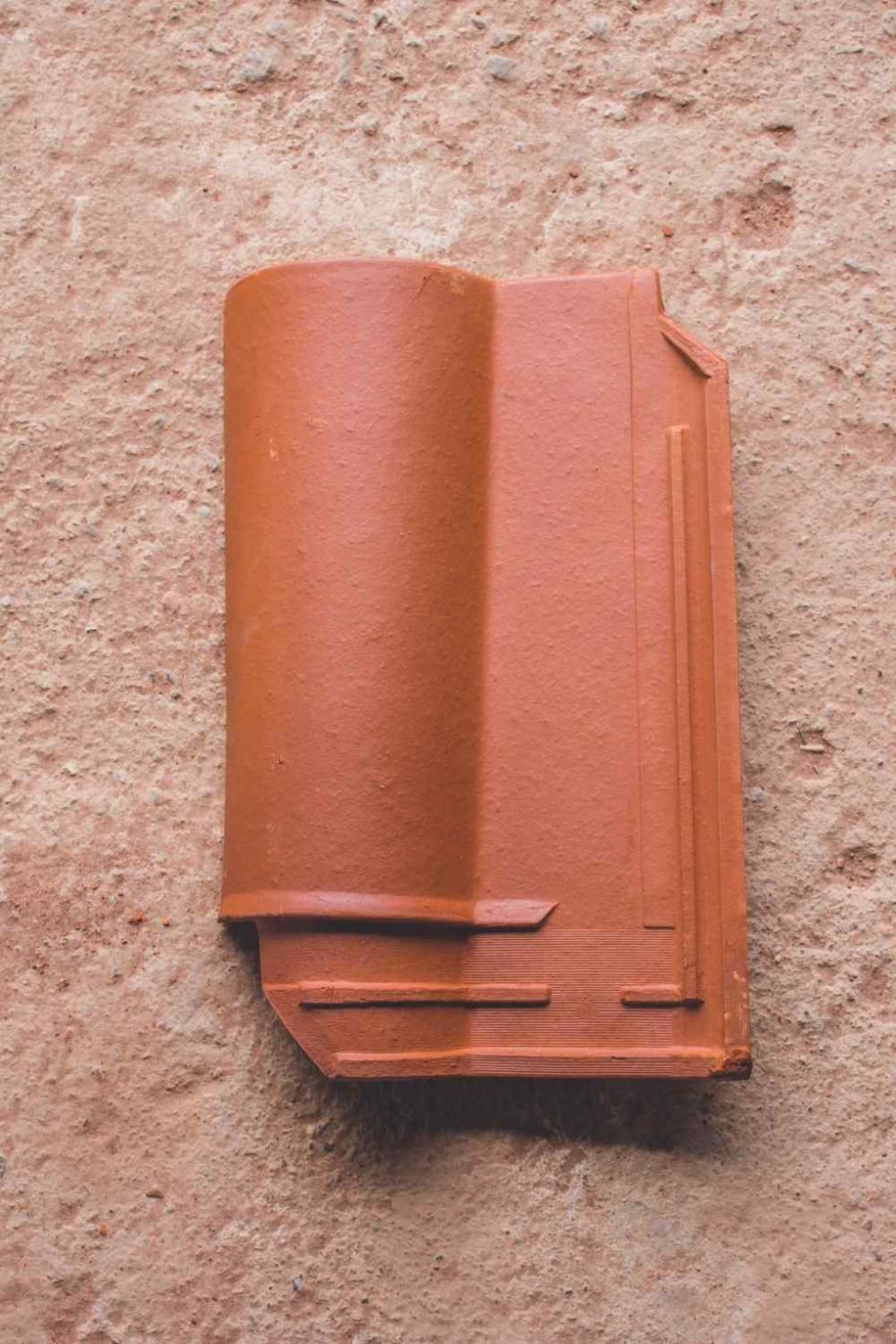

- Pressing Process The cuboid shaped clay is pressed in a mold, shaped as a tile and over here the name and the logo will be imprinted on the tile. The deformed tiles are reshaped and smoothened by using a knife to convert it to the right shape.

- Drying Process he shaped tiles are placed on specially designed racks where they are left to dry naturally. This drying phase is crucial as it allows the tiles to lose excess moisture gradually, minimizing the risk of cracking or warping during later stages. The duration of the drying process may vary depending on ambient temperature and humidity conditions.

- De-airing Process The dried tiles go through a de-airing procedure, which ensures that all trapped air molecules are expelled. This step is essential for preventing air pockets within the tiles, which could lead to structural weaknesses or imperfections after firing.

- Burning Process After de-airing, the tiles are transferred to a kiln for the burning process. This stage involves firing the tiles at high temperatures, which hardens and solidifies the clay. The firing process not only strengthens the tiles but also imparts their final durability and resistance to weathering

- Quality Check Once the firing is complete and the tiles have cooled down, they undergo a thorough quality inspection. This step ensures that each tile meets the required standards in terms of shape, size, surface finish, and structural integrity. Any defective tiles are removed from the batch.

- Storage The final, inspected tiles are then stored in a dedicated warehouse. Proper storage conditions are maintained to protect the tiles from damage and prepare them for distribution